View sample Environmental Supply Chain Management Research Paper. Browse research paper examples for more inspiration. If you need a management research paper written according to all the academic standards, you can always turn to our experienced writers for help. This is how your paper can get an A! Feel free to contact our writing service for professional assistance. We offer high-quality assignments for reasonable rates.

The issue of green or environmental supply chains (these two terms will be used interchangeably) is critical for the successful implementation of what has been defined industrial ecosystems and industrial ecology. But more significantly, this topic is important due to the environmental impacts of multiple organizations across a supply chain rather than focusing on a single organization. Waste and emissions caused by the supply chain have become the main sources of serious environmental problems ranging from such issues as global climate change to hazardous waste generation and acid rain. Organizations have a number of reasons and pressures for implementing environmental supply chain policies, from reactive regulatory reasons, to proactive strategic and competitive advantage reasons. This paper will focus on a review of established and emerging research and practice on environmental supply chains and their management. In a way, the article serves the dual purpose of presenting the state of the art as well as the state of the debate.

Academic Writing, Editing, Proofreading, And Problem Solving Services

Get 10% OFF with 24START discount code

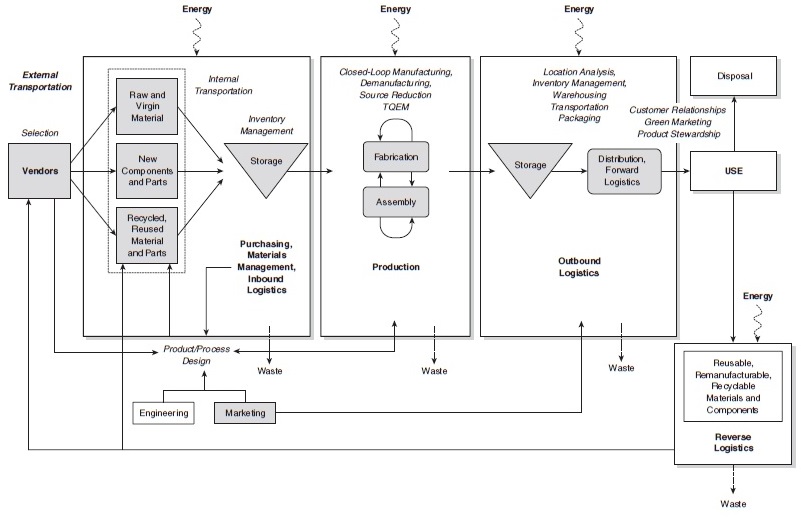

For the purposes of this research-paper, the supply chain “system” includes purchasing and inbound logistics, production, distribution (outbound logistics and marketing), reverse logistics, and input-transformation-output-feedback definition of a system. In the following, we shall see that other definitions exist as well. The first three categories are part of the well-known value chain concept espoused by strategic thinkers such as Porter. The last functional element, reverse logistics, is one of the more recent areas of focus by supply chain researchers. Figure 28.1, described later, brings these factors together.

We begin our discussion and debate faced by development of a definition for environmental supply chain management. After a brief discussion concerning the definition of supply chain management and green supply chains, the discussion and presentation of issues turns to our three defined areas. Some practices, research, and evolving issues are discussed for each of them. Then, we will present an integrative look at the whole system and common issues. We will also present what the future may look like and some possible emerging debates.

Definitions

Supply Chains and Supply Chain Management

The concept of supply chains and supply chain management is a relatively recent (within the last 20 years) managerial principle. The topic and field have evolved with input from a number of disciplines and fields including purchasing, marketing (distribution channels), logistics, and operations management. The issues include management of inventory, customer-supplier relationships, delivery time, product development, and purchasing just to name a few related managerial areas.

A textbook description of supply chain management by Handfield and Nichols (1999) provided the following definition for a supply chain: “The supply chain encompasses all activities associated with the flow and transformation of goods from raw materials (extraction), through the end user, as well as associated information flows. Material and information flow both up and down the supply chain” (p. 2).

In this description, the supply chain is considered a linear process. The circular and systemic philosophy of “ecosystem” thinking is not explicitly included. Thus, from this textbook perspective, the integration of the full cyclical supply chain is not considered central to its definition. Few textbooks seem to diverge from this definition. This small example is exemplary of common wisdom within the supply chain management field. Developments in greening supply chains have yet to diffuse through the general literature. Practice in this area seems to be as sporadic and diverse as the field of study, with green supply chains poorly and/or erratically practiced and investigated.

Green Supply Chain Management—What Is It?

Green supply refers to the way in which innovations in supply chain management and industrial purchasing may be considered in the context of the environment. (Green, Morton, & New, 1996, p. 188)

Environmental supply chain management consists of the purchasing function’s involvement in activities that include reduction, recycling, reuse and the substitution of materials. (Narasimhan & Carter, 1998, p. 6)

The term “supply chain” describes the network of suppliers, distributors and consumers. It also includes transportation between the supplier and the consumer, as well as the final consumer . . . the environmental effects of the researching developing, manufacturing, storing, transporting, and using a product, as well as disposing of the product waste, must be considered. (Messelbeck & Whaley, 1999, p. 42)

From these three definitions, we see that there is a range of author focus and purpose on green supply chains and their management. Research or practitioner field (i.e., purchasing, operations, marketing, or logistics) also influences the definition. The definition of the purpose of green supply chains, which range from reactive monitoring of general environmental management programs to more proactive practices such as the Rs (e.g., reuse, remanufacture, recycle, and reclamation) of environmental management and incorporating “innovations” also differ. This lack of consensus in practice and definition of green supply chain is not surprising, since its foundational elements of corporate environmental management and supply chain management are both relatively new areas of management study and practice.

The discussion in this research-paper will follow the last of the four definitions encompassing most of the customer-supplier supply chain. The supply chain has both a supply side and a demand side, and both of these sides need to be managed.

Figure 28.1 shows a number of environmental issues as well as operations within a typical supply chain. The primary focus in this figure is the management of materials that flow through the supply chain and relationships among the various functions. Vendors (who have their own internal and external supply chains) supply the necessary materials. The materials may include raw and virgin material, parts, and components from original manufacture and recycled, reusable, or remanufactured materials. There are environ-mental implications depending on the focus of acquisition activities at this stage. These materials are transported from various vendors, which also may be a determinant of environmental impact of the product or material to be procured. For example a recycled material from a distant location may not be as environmentally sound as a virgin material from closer locations. The policies for selection of vendors are a central issue for purchasers. Vendor selection criteria and policies are briefly reviewed. These materials are then stored and may be managed under the auspices of the purchasing function. The product and process design will influence each of the major functions. This influence requires management by various functions and vendor(s) contributing to the product and process design. Included in design issues will be such topics as life cycle analysis (LCA) and design for the environment (DFE) concepts.

The production function is composed of assembly and fabrication. In this function, environmental issues such as closed-loop manufacturing, environmental management systems (EMS; e.g., total quality environmental management [TQEM] and ISO 14000 environmental management standards), demanufacturing, and source reduction all play some role. Outbound logistics includes such activities and issues as transportation determination, packaging, location analysis, and warehousing, as well as inventory management (for finished and spare parts good items). Marketing’s influence is through customer relationship management as well as green marketing concerns. The “use” external activity is the actual consumption of the product, a situation where product stewardship plays a large role. At this stage, field servicing may occur, but from an environmental perspective, the product or materials may be disposed or return to the supply chain through the reverse logistics channel. Within this channel, the product can be deemed reusable, recyclable, or remanufacturable. The reverse logistics function may feed directly back to an organization’s internal supply chain or to a vendor, starting the cycle again. Each major supply chain activity consumes energy and generates some level of waste. Reduction in energy usage and waste generation are issues that need to be addressed throughout the supply chain.

Keeping in mind the relationships presented in Figure 28.1, each of these major functions (purchasing, production, outbound logistics, and reverse logistics) will now be discussed.

Purchasing And Inbound Logistics

The purchasing and procurement function involves the acquisition of materials from suppliers to meet the needs of producing the organizational product or service. Purchasing includes duties such as vendor selection, material selection, outsourcing, negotiation, buying, delivery scheduling, inventory and materials management, and to some extent, involvement in design.

Figure 1 Management of Materials and Relationship Among Functions

General Green Purchasing Practice

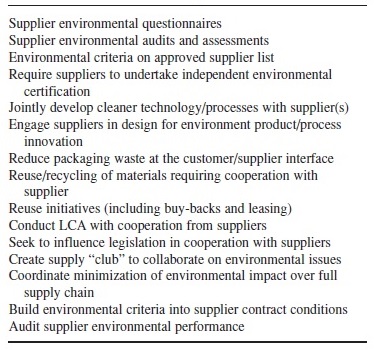

The research in this area has focused on how management practices green purchasing. Empirical surveys have focused on the distribution of practices and anecdotal articles have provided examples of green purchasing practice. Within this area, “policy entrepreneurs” were found to be drivers of the firm’s environmental purchasing activities. Also, the roles of middle managers and upper managers in green purchasing were found to be critical for the success of this function and its adoption by organizations. Green purchasing has a number of environmentally based initiatives that may be incorporated into the purchasing function; these are summarized in Table 28.1. These initiatives include both proactive and reactive measures. To manage these initiatives successfully, a number of factors need to be included in managing the supplier-customer relationship. These factors include long-term strategic relationships and contracts, early involvement by the supplier and customer, building trust, incorporating linkages among levels of management and functions, early involvement of suppliers in design of product and process, joint teams and problem solving, and a focus on value rather than cost. How well and which of these factors aid in the greening of the purchasing function and supply chain require further validation and evaluation. Some of these more complex relationships may overshadow other criteria and goals to overshadow environmental criteria.

Table 1 A Listing of Environmentally Based Initiatives for the Purchasing Function

In some empirical surveys of green practice by the United States and international purchasing managers, corporations are still relatively reactive when integrating environmental issues into supply chain management practices. Some of these findings included a focus on reducing liability and meeting regulations rather than environmental partnering when a buying firm selects suppliers, a focus on recycling, rather than reuse or source reduction (defined by low-density packaging), and scrapping or dumping as the major waste elimination strategy.

From a strategic organizational perspective, decentralization versus centralization of corporate procurement is a concern. A determination of whether a strategic environmental policy can be better maintained throughout an organization with decentralized purchasing decision making. Monitoring green product procurement becomes more complex in a decentralized environment. Yet a decentralized decision environment may also present greater opportunity for purchasers to find and build relationships with geographically closer vendors. This close proximity makes transportation more efficient and less costly and may make monitoring and auditing of supplier activities more effective. In addition, multinational conglomerates who have a broad product family and many subdivisions may find it more feasible to allow divisions to determine their own supplier and purchasing environmental requirements. Within this decentralization, not all portions of an organization may include supplier impact programs.

There is also a concern of who should be responsible for environmental issues in purchasing. There is an organizational decision issue on whether an organization’s purchasing department should be responsible for managing the environmental performance of the supply chain. Since they are responsible for cost, delivery, and quality issues, is it fair to add another level of responsibility to this function (especially with the management of environmental surveys of their suppliers)? A solution may be to help improve supplier environmental performance rather than just an evaluation.

Purchasing managers believe that economic reasons form the largest barrier for implementing green purchasing. Many managers also believe that recycled materials are more expensive and scarce and thus provide economic and operational barriers to purchasing these types of materials. A major reason why organizations continue use of new materials is because customers require them to use virgin material.

Public policy is a major driver of environmental and social decisions in organizations, whether or not costs of recycled goods are more expensive or cheaper. Some have argued that the cost of recycled products may be greater due to the expense of reverse logistics channels with estimates that reverse logistics channels and processes may add 30% or more to the cost of a recycled product. Yet for some products and commodities, recycled material can be less expensive to purchase than comparable virgin materials can be. Part of the difficulty is that estimation of costs (and other factors) cannot be completed without more effective LCA type tools for analysis of total costs. Various products and materials will also have differing cost structures resulting in dissimilar perceptions on cost, probably contingent on product type and industry. In addition, social costs (externalities) are not typically included in the valuation and costs of products and materials.

Another issue in purchasing is the selection of materials or vendors. One of the requirements in this area is to determine what is and is not green. For example, the decision to purchase materials that are less toxic versus those that may mean more energy efficiency cannot easily be determined. To help address this some tools based on LCA and DFE have been developed. Yet these are still very imperfect tools, models, and philosophies. Subjectivity and judgment play a large role. An issue is whether purchasing managers are motivated and capable of evaluating and selecting environmentally preferable materials and vendors.

Vendor Selection

One of the more important functions of green purchasing has to do with the external relationships of the purchasing function, especially for selection of vendors. Much of the vendor selection research has focused on whether companies include environmental criteria in their selection processes, the criteria for selection, and tools for their selection. This research has been primarily anecdotal and prescriptive. Descriptive, broad, empirical research has been minimal.

Purchasing managers typically favor reactive measures for evaluation (e.g., hazardous waste management, public disclosures, and meeting regulatory requirements). A primary reason for reactive measures has to do with liability concerns (e.g., superfund penalties may be traced to customers of bad suppliers) as well as making sure that the supplier will be available for the long run to help maintain continuity of supplies.

Supplier selection decision tools have been grouped into five sets of tools: (a) the categorical method, (b) the weighted point method, (c) the matrix approach, (d) the vendor profile analysis (VPA) method, and (e) analytical hierarchy process (AHP) based approaches. Only one of the models (i.e., AHP) contains both quantitative and qualitative factors. The literature on supplier selection has not explicitly included and evaluated environmental factors and much work needs to be completed in this area. Typically, incorporating these additional factors in decision models would be up to management and decision and could be completed with little additional effort. Integrate risk analysis into vendor selection is also needs to be considered for green supply chains. This goal is not typically covered in approaches that are more traditional.

Certification (selection) requirements may be easier to address for organizations by requiring some form of thirdparty certification, specifically ISO 14001 certification. ISO 14001 certification may be adequate for organizations that do not wish to audit or evaluate suppliers for selection. Yet a number of suppliers (primarily small suppliers) are not necessarily supportive of an ISO 14001 certification requirement. Imposing a certification standard on a small supplier may actually have negative effects. Obtaining certification is time-consuming and expensive. They argue that a small supplier may have better business and environmental payback by putting resources into actual process improvements rather than by developing an environmental management system with its supporting bureaucracy, and in the some cases, a small supplier might be forced out of business because it lacks the resources needed to meet buyer environmental requirements. A small supplier may wish to acquire ISO 14001 certification so it does not have to meet varying environmental vendor certifications from multiple customers. A potential problem with forgoing organizational vendor certification and evaluation in favor of ISO 14001 certification, is that there is no guarantee that ISO 14001 organizations are compliant, much less environmentally proactive. There are other approaches for ISO 14001 certification where groups or networks of smaller enterprises may aggregate their resources to get one certification that would cover all of them. This collective ISO 14000 certification has been has also been called the “Hackefors” model.

Inbound Logistics

One of the issues in delivery (and production) is the use of just-in-time (JIT) practice. This practice is meant to reduce inventory, thus eliminating costs and waste. For example, less storage and warehouse space is needed. This practice reduces the necessary overhead and resource consumption needed to manage this inventory. JIT seems to be an environmentally sound practice, yet when considered overall, the environmental savings can be deceptive. For example, the major method to lessen the amount of inventory is to deliver and produce in small batches. These smaller batches mean more deliveries, thus raising fuel consumption and traffic congestion. Investigation of these trade-offs is still occurring in the literature and requires significantly more investigation before consensus can be reached. But some of these issues are mitigated with such practices as on-site suppliers or those that are in close proximity for JIT reasons. Another factor related to JIT and supplier management is that fewer suppliers are usually used in a JIT environment. This means better forecasting and fuller loads could be planned. Of course, this delivery approach will be dependent on demand levels and characteristics.

Another issue facing inbound logistics (and outbound as well) is freight consolidation. Waiting for freight to become a full load (full truckload or trainload) may lead to longer lead times but may yield savings and be environmentally preferable. Another issue is mode selection. Some transport

modes like rail and barge use less energy or use energy more efficiently than other modes like road haulage and air cargo. In this case, flexibility, timing, and speed are tradeoffs to cost and environmental factors. The transport mode decision determines which transport option to use and often affects traffic congestion and air pollution both directly and indirectly. Carrier selection, a part of supplier selection, is an important inbound logistics decision. Transportation is important to all industries.

The major question in these examples is whether companies are capable and willing to make the trade-offs. An issue that arises relates to any major environmental issue: When does the environment play a large enough role to overcome other performance metrics? As well, the addition of a third party (third-party carriers and logistics managers are quite popular) into the decision process makes it more difficult for the vendor-customer relationship. Who makes the decision on mode and freight consolidation, especially when organizations may have differing environmental strategies?

Production

The manufacturing and production function’s emergent role in corporate environmental management has been addressed in the literature. The internal supply chain’s performance can best be managed within this function. Since a number of reviews on environmentally conscious manufacturing have been completed, we will focus only on a few of the major principles in this function.

TQEM, ISO 14001, and other EMS play a large role in managing the internal operations of an organization. Similar to the concept of total quality management (TQM), it is hard to get a standardized definition and practice of TQEM and EMS. Many of the components of ISO 14001 build on TQEM-like concepts as well. TQEM is a managerial philosophy rather than a hard technology or program, with a number of tenets (some of which are also espoused in dealing with suppliers as well). Some of the tenets of TQEM include empowerment of employees, continuous improvement, team efforts, interfunctional collaboration, and leadership elements. There are issues in each of these areas; one of the most important of these areas, from a managerial perspective, is empowerment and employee involvement.

Empowerment allows workers to attain responsibility for decision making. Whether employees are capable of making these environmental decisions is an important barrier. Liability and corporate risk for such sensitive and sometimes technically complex issues are part of the environmental decisions that need to be considered when incorporating employee empowerment. Similar to quality control, which has evolved to include everyone in an organization, can environmental decisions be allowed to become as pervasive? These questions are critical since employee involvement is a practice that researchers and practitioners believe are central to pollution prevention in the production function. In one study of automotive manufacturers, worker participation in environmental decisions was emphasized. But even with this emphasis, findings showed that the amount of worker participation (and its significance) was much less than the supposed involvement as mentioned by management was. Inadequate technical expertise in environmental issues is a primary reason for limited worker participation and environmental decision empowerment. This study also points to a need for a better definition of worker participation, especially when it comes to environmental issues. Participation can range from putting an item into a recyclable bin to serving on a design for environment project.

The principles of demanufacturing are also of importance within the production portion of the environmental supply chain. Demanufacturing includes disassembly, remanufacturing, and material recovery principles. The investigations in this area have predominately been on the development of tools to aid in the management of these processes. The two major categories of tools include those that aid in designing products for demanufacturing (disassembly) and those used to optimize or control the demanufacturing process. The effectiveness of demanufacturing from an environmental and economic perspective is still in its infancy. Currently, in a number of industries, remanufacturing and reverse logistics are relatively novel concepts. Since this operation is not as mature, a number of inefficiencies still exist since organizations will not heavily invest in the operation until marginal costs are reduced through economies of scale improvements. To be economically feasible, operationally feasible, and environmentally benign, the systems flowing into and within the organizations operations need further development. The determination of whether the lengthening of the life of these products and materials is worth the additional efforts of energy use and waste generation has yet to be fully explored.

Closed-loop manufacturing is one of the internal measures that can be used to improve the environmental performance of the internal supply chain. The philosophy of zero emissions (similar to zero defects of many TQM programs) is what drives internal closed-loop manufacturing practice. Closed-loop manufacturing is a process of producing products with no negative environmental impact. Currently, much of the emphasis on closed-loop manufacturing is on development of supporting technology. This internal loop helps to lessen some waste streams that flow from the production function, but may require additional energy and resources to function and maintain. As part of the source-reduction philosophy closed-loop manufacturing a related issue to the zero-emissions philosophy is substitutability, which has become much more popular with design for the environment linkages. For example, substitutes for environmentally toxic materials such as solvents with aqueous solution for processes and powder paint for liquid paint are examples of using substitutes to reduce and eliminate emissions. The determination of life cycle impacts of these substitutes is still a problematic proposition. The investigation of managing in this environment seems to be almost nonexistent.

Distribution And Outbound Logistics

Whereas purchasing and inbound logistics focus on managing the vendor-organization relationships of the supply chain, the distribution, and outbound logistics function is meant to address the organization-customer relationship dyad. Customer relationships within corporate environmental practices include green marketing, product stewardship, and outbound logistics topics.

Customer Relationships

Customer relationships are greatly influenced by green marketing policies. Some studies have found that ultimate individual consumer interest in the environment and environmentally sound products is quite substantial, even though there has been a slight decline over the years. This interest along with government regulations are two external pressures that flow throughout the supply chain. Studies have shown that many companies are putting pressure on their suppliers and suppliers are listening to corporate customers as well as the end user.

One of the controversies in green marketing and customer relationships is whether customer interest in environmentally sound products relates to actual purchase. Various studies have shown that interest is usually higher than actual purchase. This argument can be made for either individual consumers or corporate and industrial buyers. Even though this issue has been shown to be an individual consumer phenomenon, the extension to corporate buyers needs a more complete evaluation.

Some studies have shown that individual consumers and business-to-business consumers (e.g., purchasing agents) have similar attitudes, actual behavior, and understanding of purchasing green products. Other studies argue that business consumers are more aware of environmental and green product characteristics and issues than individual consumers are. Whether or not these market groups have equal levels and understanding of environmental issues with regard to purchasing products will influence organizational marketing strategies and practices.

Another issue related to marketing to customers is to understand their hierarchy of criteria for purchasing. Price, quality, and convenience criteria are still at the top of this hierarchy. An issue that green marketers face is how to make environmental criteria more important. Marketers have several options to achieve this goal including increasing the importance of ecological compatibility (e.g., explaining the effects of poor environmental products), changing beliefs about a particular product (e.g., disposable diapers may actually be more environmentally conscious than cloth diapers), and explaining the additional environmental benefits in addition to the other criteria. Incorporating money-back guarantees to overcome some of the concerns about quality/price of environmentally beneficial products may be a method to increase their attractiveness. These recommendations still require significant study. Differing definitions and expectations of buying organizations may have some impact on the green marketing strategy of an organization.

Product stewardship also plays a significant role in an organization’s relationships with its customers. Similar to the concepts of DFE, LCA, and TQEM, product stewardship principles affect the broader supply chain. Product stewardship has been defined as the minimization of the product’s harmful effects on the environment in every stage of its product life cycle from design and development to manufacturing, distribution, use, and disposal. The practice and literature seems to focus on the delivery and take back aspects of product stewardship and customer relationships. This is a reason that we have left product stewardship discussion until this function of the supply chain. Practically, this concept is one of the foundational elements of the chemical industry’s Responsible Care program. Under Responsible Care principles, chemical producers are required to evaluate the handling of their products by customers to ensure, where possible, that safety measures are in place.

Product stewardship principles have brought innovation to the way business is completed in the supply chain. One such example is the servicizing of products. Servicizing is especially true in industries such as the chemical industry whose materials and products contain significantly hazardous and environmentally sensitive materials. Servicizing includes changing transactions from a volume and sales orientation to a service orientation. As an example, instead of selling solvents to a manufacturer for cleaning circuit boards, a chemical supplier might manage the manufacturer’s cleaning. For managing the cleaning operation, the supplier would be paid on a “per-circuit-board-cleaned” basis. This shift in focus from sales to service creates a profit incentive for the supplier to clean more circuit boards with fewer chemicals. In some industrial sectors, especially automobile manufacturing, this shift from chemical sales to services has already been established. This service orientation, similar to leases for product take-back measures for electronic equipment, requires significant change in management and accounting measures used by an organization.

Outbound Logistics

The outbound logistics function has numerous implications for greening the logistics function. The design of a logistics network and its planning are two strategic issues facing logistics managers in this function. Many trade-off decisions need to be made with regard to the firm’s market, customer, product, and logistical resources. Examples of typical logistics decisions include options such as direct versus hub-and-spoke delivery, central warehousing or distributed network, intermodal or single mode transportation, and outsourcing third-party services or private fleet for distribution and transportation. Some of the design and management criteria that support environmental planning in this area include fewer shipments, less handling, shorter movements, more direct routes, and better space utilization. But each of these issues includes trade-offs among delivery time, responsiveness, quality and cost, as well as environmental performance.

Warehousing and delivery packaging design are two important issues in outbound (and inbound) logistics and distribution. Warehousing, other than land use requirements, also generates a significant portion of packaging waste in the supply chain. Standardized reusable containers, good warehouse layouts, and easy information access all cut storage and retrieval movements, save on operating costs, and are environmentally sound. Freight consolidation functions and “breakbulk” operations carried out in warehouses also have the potential of utilizing transport capacity more efficiently, thus minimizing the environmental impact of the outbound transport system.

Packaging has been a very sensitive issue among European manufacturers and consumers. The presence of packaging take-back laws has caused many organizations to rethink the design of their product’s packaging as well as how to manage the packaging delivery and logistics, once it is used. One controversy that seems to be growing in the packaging area is whether single use packaging is more environmentally sound than reusable packaging. For example, the Association for Beverage Cartons and the Environment has reported no specific benefit for using either type of packaging after 15 studies were undertaken. Part of the difficulty in determining which part of this debate is correct is the poor development of LCA tools.

Another packaging debate focuses on consumer perception and acceptance of green packaging. While most people regarded packaging as bad for the environment, they still chose packaged over unpackaged alternatives when buying. Some companies, after instilling more environmentally preferable packaging, had increases in their market shares—one such company is Nestle Corporation. Packaging choice relates to consumer attitudes and behavior. Whether these situations are applicable to industrial buyers and buying still requires investigation. A study of environmental packaging and its influence on industrial buying is an issue that has not received much attention. Some issues relevant to purchasing practice after passage of packaging laws have been investigated in the literature.

Reverse Logistics

Reverse logistics incorporates the return of materials, components, and products back into the “forward logistics” chain. Reverse logistics is the return, upstream movement of a good or material resulting from reuse, recycling, or disposal with the minimization of waste, which results in more efficient forward and reverse distribution processes. It has been the function that “closes the supply chain loop.” There is significant research occurring this time related to closing this loop.

Reverse logistics operations include the following major steps: collection, separation, densification or disassembly, transitional processing, delivery, and integration. The operational emphasis is dependent on the type of material or component that flows in the reverse logistics channel. For example, disassembly will be required for copy machines, whereas plastic bottles would require densification.

Since reverse logistics is a competency that does not exist in most original equipment manufacturers and organizations, outsourcing to third-party logistics specialty companies to manage operations in this function have become very popular. The development of such third party service providers may provide potential competition to original equipment manufacturers, if these reverse logistics organizations decide to demanufacture and remanufacture products.

Pohlen and Farris (1992) summarized some of the practical issues facing reverse logistics: (a) most logistics systems are ill equipped to handle product movement in a reverse channel; (b) reverse distribution costs may be up to 9 times higher than moving the same product from producer to consumer; and (c) returned goods often cannot be transported, stored, and/or handled in the same manner as in the forward channel. In addition, Bettac, Maas, Beullens, and Bopp (1999) referenced a German study by Junemann (1995), which found that reverse distribution channels may be up to 14 times longer transportation distances then regular disposal and incineration. In their study of the furniture industry, Handfield, Walton, Seegers, and Melnyk (1997) found that reverse logistics scored lowest, in terms of progress, among all the functional areas. This finding supports the issue of the immaturity of this function and also provides ample opportunity for improvements and growth.

A significant amount of work in this field has focused on analytical (mathematical) modeling. This perspective of reverse logistics incorporates a number of managerial and modeling issues. Two major issues include inventory and production planning management. The inventory management of these systems is difficult since return logistics flows are more difficult to forecast requiring increased flexibility in terms of capacity and equipment, as well as additional safety stocks for inventory to manage the variability and uncertainty. The production planning area is more closely related to demanufacturing issues presented earlier. In summary, tools and models for disassembly scheduling, planning, and control are still in their infancy. The proposed approaches have looked at altering standard manufacturing models like MRP systems. A series of quantitative model

ing approaches for such issues as network design, systems evaluation, and so forth were not part of this review of the literature. Noting that a number of models in this area are adjustments to current models, a question arises, similar to the issue on vendor selection models, of whether new models need to be developed.

Other than quantitative modeling approaches, the reverse logistics research is the most immature of all the functions discussed in this paper. Principles for managing reverse logistics channels have yet to be developed, much less investigated, but it is the fastest growing area.

Emerging Issues

A number of emerging issues that encompass environmental supply chain management or that are common across the supply chain are briefly presented.

Small Companies and Environmental Supply Chain Management

Small organizations’ voluntary involvement in environmental practices in the supply chain is rare. Small manufacturers do have some basic environmental practices (especially recycling initiatives) in their organizations. Investigation of strategies to help small organizations gain environmental savings is an emergent area of research and emphasis. Including savings in the form of less expensive environmental management infrastructure and services, accelerated and less expensive information flows, decreased incidence and intensity of land-use conflicts, and an enhanced ability on the part of the public sector to enforce environmental regulations. Development of interfirm networks could be a way to help small organizations become more effective environmental partners.

Government and Legislative Roles in the Green Supply Chain

Regulatory schemes have been quite powerful in development of environmental supply chains. For example, the Waste Electrical and Electronic Equipment (WEEE), Restriction on Hazardous Substances (ROHS), and the Registration, Evaluation, and Authorisation of Cemicals (REACH) directives in the Europe Union have had significant influence on organizations investigating and improving their global environmental supply chain management practices. The influences at a policy level of voluntary, performance-based, market-based, or command-and-control mechanisms for development of environmental supply chain management can provide great insights into the types of regulatory pressures that will make supply chains more environmentally sound. For example, government-led green purchasing initiatives have occurred at all levels of government. The basic idea is that by purchasing large quantities and selecting preferred suppliers, the government could shift product markets to favor one product type over another. Thus, by government purchases providing an earlier and larger market for green products, it allows firms to lower costs through scale economies and learning-by-doing.

Integral and Emerging Issues

Much of the research completed on environmental supply chain management has been narrowly focused on a single functional area. A complete and integrative evaluation and monitoring of performance is required. A systems perspective has yet to permeate the literature. The corporate environmental management and practices are still evolving with significant areas for further research and development in DFE, LCA, and product stewardship. The representation of the supply chain and its topics in Figure 28.1 itself is not exhaustive. Additional factors and issues can be integrated. How to make sense of all this and the attempt to develop theory to explain various managerial phenomena is a difficult proposition. These theoretical and investigatory issues can be grouped into strategic and operational levels of analysis (with some overlap). The more strategically oriented issues include industry differences, evolving organizational forms, linkage to environmental strategy, and the relationship between organizational performance and green supply chains. Operationally oriented issues include performance measurement, third-party certification, product life cycles, and LCA.

Industry Differences

The investigation of industry differences in environmental supply chain practices is also an issue that has been observed in each of the functions. Industrial differences in how organizations incorporate environmental strategy. Heterogeneous stakeholder pressures will cause industries to respond differently to environmental pressures. Some industries will face greater regulatory pressures to incorporate environmental practices, while others may face competitive forces to alter environmental practices. But an additional difficulty within supply chains are variations in the industry involvement; for example, it is difficult to only have a sup-ply chain made up of chemical industry companies.

Evolving Organizational Forms

Part of organizational supply chain formation will be affected by new organizational forms defined as networked or virtual organizations. How to form networked organizations with minimal environmental impact is an issue. These organizations are meant to form and dissolve rapidly. Responsibility for any environmentally malignant behavior by the company or its members may provide unforeseen liabilities and consequences, with responsibilities of this behavior difficult to trace. Having an initial environmental strategy, which drove the formation and operations of this organization, is not usually one of the concerns of forming these types of organizations.

Linkage to Environmental Strategy

The influence of varying corporate environmental strategies with different members of the supply chain having diverse environmental strategies arises in environmental supply chain management. Incongruity of supply chain member environmental strategies may cause the whole supply chain environmental performance to be less efficient and effective due to poor local performance (the weakest link argument).

The Relationship Between Organizational Performance and Green Supply Chains

The basic question here is whether environmental supply chain management improves organizational environmental, economic, and/or operational performance. There have been investigations of organizational corporate performance and environmental performance; yet these studies have found conflicting evidence (at the strategic level of analysis) between environmental management and organizational performance. Ample opportunity exists in this area to identify how various environmental management policies and principles effect corporate performance, as well as why variations in results have been occurring.

Performance Measurement

How to measure supply chain performance in general is an emerging issue in basic supply chain management practice. Design and implementation of environmental performance measures into the supply chain has been rarely discussed much less implemented in the supply chain management literature. Investigations of tools, practices, metrics, and methodologies are needed in this area.

Product Life Cycles

The dynamic nature of the product life cycle and its implications on various environmental supply chain practices can be significant. The organizational emphasis on which functions an organization develops and supports in the green supply chain is dependent on the product’s (and industry’s) marketing life cycle. That is, if a product is in the early innovation stages or later maturity or decline stages may influence whether the organization is putting more emphasis on the procurement stage (selecting appropriate vendors) or on reverse logistics (enough products and material exist for efficient reverse logistics channels). Thus, organizations planning for long-term green supply chains need to be aware of the necessary requirements for strengthening the supply chain as it matures.

Life Cycle Assessment

The issue of LCA looms large in each of the functions. The lack of appropriate LCA tools makes the appropriate decision of product and material selection, supplier selection, production technology, delivery mechanism, and transportation selection difficult to determine. How well decisions perform environmentally, either practically or for research measurement purposes, all require effective LCA measurements. Yet suppliers and organizations find LCA is one of the most problematic aspects of managing the supply chain. Managing the overall supply chain without agreed upon LCA measures will require more art than science.

Information And Knowledge Management

The role of interorganizational information systems and transferring of knowledge and learning across the supply chain has significant practical implications. The movement of material through the supply chain is quite evident; the movement of information and knowledge is just as critical. Ranging from LCA information to inventory data, the use of information for designing, managing, planning, and implementing environmental supply chains arises. E-commerce plays a large role, and its implications are still under evaluation. For example, e-commerce requires numerous point transportation (causing greater environmental burden) but also shares information of excess product and material that may be useful to other organizations (lessening waste). These and numerous other trade-offs require more investigation.

Sustainability. The current corporate social responsibility focus of supply chains has extended to go beyond just environmental and economic factors. Researchers and practitioners are incorporating nonenvironmental social factors into various functions of the supply chain. For example, sweatshop and child labor, equity, and poverty issues that focus on human-centered social issues have gained in importance. The difficulty of incorporating general sustain-ability topics in with environmental issues in the supply chain is the possibility of losing focus on the environmental issues. The evaluation of the relationships of these “triple bottom line” items is an area of significant research within sustainability and corporate social responsibility.

Summary And Conclusion

We have reviewed a number of issues related to environmental supply chains and their management. The structure of the presentation was based on four major functions that could be considered as core activities within the environmental supply chain. These functions included purchasing and inbound logistics, production, distribution and outbound logistics, and reverse logistics. A number of integrative issues potentially affecting each of these functional areas were then presented. Even in this relatively new field of environmental supply chain management a number of debates have emerged, within and between functions. It

has been found that most of the literature on environmental supply chain management has been descriptive, anecdotal, and/or prescriptive. Much of the literature has investigated small portions of the whole supply chain. With only a few empirical studies, which have been exploratory, the amount of generalizable knowledge and theory development in this area is almost nonexistent. To truly address these emerging debates and issues, effective research agendas and methodologies will be required. Even then, the debates may never truly be answered. As in all environmentally based research arenas, tools, techniques, and theory from a number of disciplines will be required for a truly complete study of this area.

Bibliography:

- Bettac, E., Maas, K., Beullens, P., & Bopp, R. (1999). RELOOP: Reverse logistics chain optimization in a multi-user trading environment. IEEE International Symposium on Electronics and the Environment, 42-47.

- Carter, C. R., & Ellram, L. M. (1998). Reverse logistics: A review of the literature and framework for future investigation. Journal of Business Logistics, 19(1), 85-102.

- Fleischmann, M., Bloemhof-Ruwaard, J., Dekker, R., van der Laan, E., van Nunen, J., & Van Wassenhove, L. N. (1997). Quantitative models for reverse logistics: A review. European Journal of Operational Research, 103(1), 1-17.

- Green, K., Morton, B., & New, S. (1996). Purchasing and environmental management: Interactions, policies and opportunities. Business Strategy and the Environment, 5(3), 188-197.

- Handfield, R. B., & Nichols, E. L. (1999). Introduction to supply chain management. Upper Saddle River, NJ: Prentice Hall.

- Handfield, R., Sroufe, R., & Walton, S. (2005). Integrating environmental management and supply chain strategies. Business Strategy and the Environment, 14(1), 1.

- Handfield, R. B., Walton, S. V., Seegers, L. K., & Melnyk, S. A. (1997). ‘Green’ value chain practices in the furniture industry. Journal of Operations Management, 15(4), 293-315.

- Jünemann, R. (Ed.). (1995). Entorgungs Logistik III: Kreislaufwirtschaft. Berlin, Germany: Erich Schmidt Verlag.

- Kitazawa, S., & Sarkis, J. (in press). The relationship between ISO 14001 and continuous source reduction programs. Inter-national Journal of Operations and Production Management.

- Messelbeck, J., & Whaley, M. (1999). Greening the health care supply chain: Triggers of change, models for success. Corporate Environmental Strategy, 6(1), 39-45.

- Min, H., & Galle, W. P. (1997). Green purchasing strategies: Trends and implications. International Journal of Purchasing and Materials Management, 33(3), 10-17.

- Narasimhan, R., & Carter, J. R. (1998). Environmental supply chain management: The center for advanced purchasing studies. Tempe: Arizona State University.

- Pohlen, T. L., & Farris, M. T. (1992). Reverse logistics in plastics recycling. International Journal of Physical Distribution & Logistics Management, 22(7), 35-47.

- Porter, M. E. (1985). Competitive advantage: Creating and sustaining superior performance. New York: The Free Press.

- Prahinski, C., & Kocabasoglu, C. (2006). Empirical research opportunities in reverse supply chains. Omega, 34(6), 519532.

- Sarkis, J. (1995a). Manufacturing strategy and environmental consciousness. Technovation, 15(2), 79-97.

- Sarkis, J. (1995b). Supply chain management and environmentally conscious design and manufacturing. International Journal of Environmentally Conscious Design and Manufacturing, 4(2), 43-52.

- Sarkis, J. (2006). Greening the supply chain. Berlin, Germany: Springer-Verlag.

- Seuring, S. (2004). Industrial ecology, life cycles, supply chains: Differences and interrelations. Business Strategy and the Environment, 13(5), 306-319.

- Stock, J. R. (1992). Reverse logistics. Oakbrook, IL: Council of Logistics Management.

- Walton, S. V., Handfield, R. B., & Melnyk, S. A. (1998). The green supply chain: Integrating suppliers into environmental management processes. International Journal of Purchasing and Materials Management, 34(2), 2-11.

- Zhu, Q., & Sarkis, J. (2004). Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. Journal of Operations Management, 22(3), 265-289.

- Zsidisin, G. A., & Siferd, S. P. (2001). Environmental purchasing: A framework for theory development. European Journal of Purchasing and Supply Management, 7(1), 61-73.